With the rapid advancement of technology, high-end manufacturing industries are placing increasingly stringent demands on production environments. Cleanrooms, as essential spaces ensuring product quality and experimental precision, are widely used in pharmaceuticals, electronics, healthcare, and other sectors. According to data from Zhiyan Consulting, the cleanroom engineering market reached a scale of 230.376 billion yuan in 2023, a year-on-year increase of 7.1%. The market is expected to exceed the trillion-yuan level by 2025, becoming the largest in the world. In this booming industry, United Pharma (Kunshan) Clean System Co., Ltd. has demonstrated keen market insight and forward-looking strategic planning. While deeply cultivating the domestic cleanroom sector, it is also actively expanding overseas, achieving a balanced and flourishing development both at home and abroad.

From Steady Growth to Industry Leadership

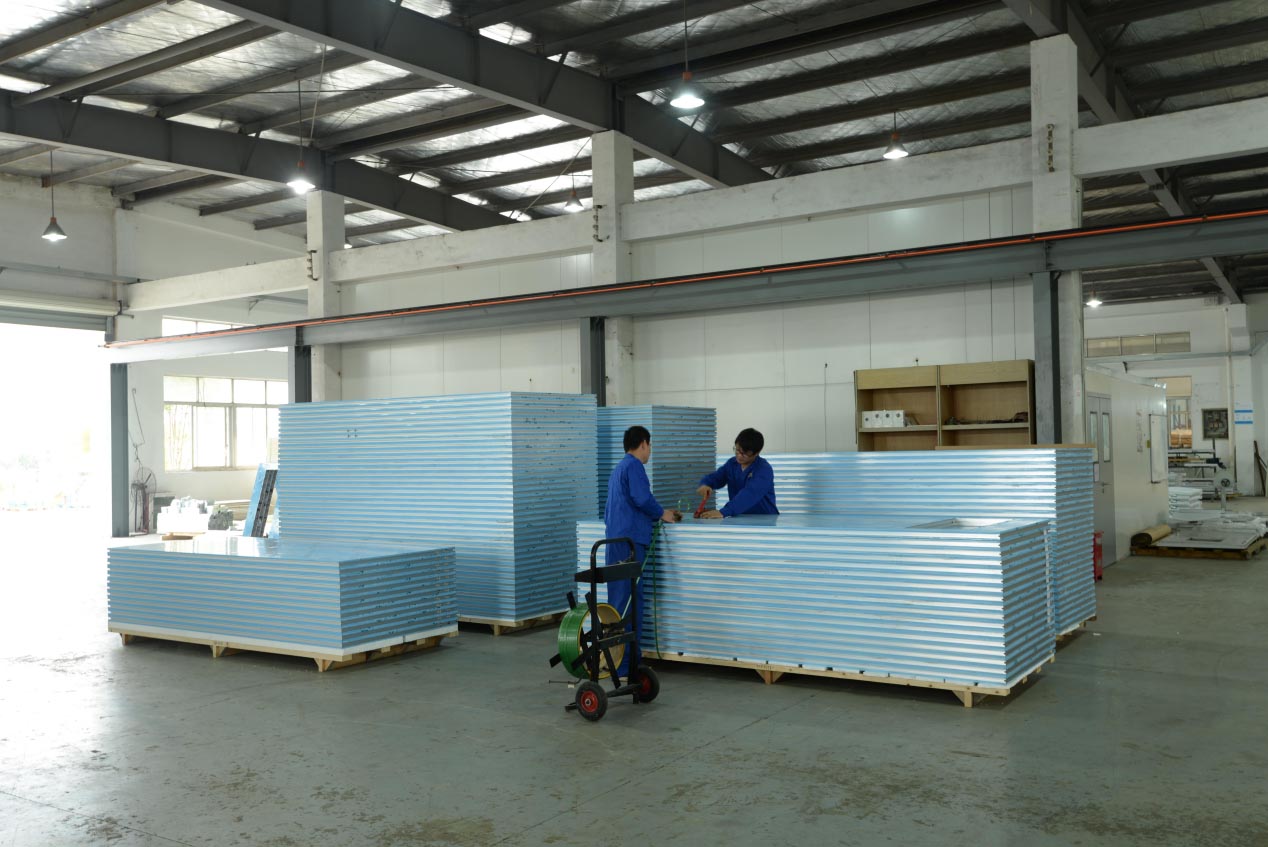

Founded in 2006, United Pharma is a comprehensive purification company specializing in the R&D, production, sales, and service of cleanroom products such as purification equipment, color steel panels, and clean doors and windows. The company is committed to providing technical development and consulting in clean technologies, cleanroom equipment, and pharmaceutical equipment. Upholding the brand philosophy of "Professionalism, Innovation, Environmental Protection, and Efficiency," United Pharma is dedicated to building high-quality clean spaces for its clients. Today, the company spans over 30 mu (approximately 5 acres), equipped with advanced processing machines such as CNC laser cutters, and boasts strong production capabilities.

Throughout its development, the company has consistently achieved breakthroughs in production capacity and market expansion. In 2008, United Pharma began exporting cleanroom partitions to markets such as India, Vietnam, Nigeria, and Egypt, marking a major step in its overseas business. The following year, the company launched installation services abroad and successfully completed several projects in Algeria, Egypt, Tunisia, and Bangladesh, receiving unanimous praise from clients and solidifying its presence in international markets. In 2011, the company continued to expand into Peru, South Africa, and other markets, steadily enlarging its global footprint. In 2012, it established a factory in Kunshan, Suzhou, which not only supported international projects but also served domestic needs, initiating a new phase of integrated domestic and international development. By 2022, a new factory was built in Qianjiang, Hubei, along with the launch of the “Easy Wall” sub-brand, further scaling up its domestic and global operations.

Currently, the company boasts impressive annual production capacity: 600,000 square meters of metal sandwich panels and hollow panels, 250,000 square meters of HPL sandwich panels, over 2,500 square meters of laminar airflow-related products, more than 3,500 pass boxes and hatches, and over 500 weighing rooms, isolators, and other pharmaceutical machinery. With project footprints in 38 countries around the world, United Pharma has been recognized as a “Gazelle Enterprise” in Jiangsu Province and has received the national-level High-Tech Enterprise certificate, securing its position as a leading figure in the cleanroom industry in China.

Innovation-Driven Excellence in Cleanroom Products

As industries like pharmaceuticals and electronics raise their standards for product quality and production environments, cleanroom construction standards are becoming increasingly stringent. In pharmaceutical cleanrooms, where hydrogen peroxide (VHP) disinfection is widely used, color steel panels must exhibit exceptional corrosion resistance. United Pharma developed the RenKang® anti-VHP color steel panel to meet these needs. With a surface coating thickness of ≥150μm—significantly higher than standard PPGI panels—this panel provides outstanding resistance to hydrogen peroxide corrosion, ensuring the long-term stability of cleanroom operations.

At the same time, United Pharma’s HPL (High-Pressure Laminate) panels also perform remarkably well in cleanroom interiors. Treated under high temperature and pressure, these panels have a dense internal structure and offer high strength, wear resistance, antibacterial performance, and moisture resistance. In 2013, United Pharma made a technological breakthrough in panel production and became a key subcontractor for the raw material production line of recombinant human insulin at Tianmai Biotech. This marked a successful domestic substitution of imported HPL panels, breaking the monopoly of foreign products. These panels remain stable under 3% hydrogen peroxide testing, do not rust, and are widely used in pharmaceutical, electronics, semiconductor, and biotechnology industries. In actual use by a major pharmaceutical manufacturer, United Pharma’s HPL panels significantly reduced maintenance costs and, with their excellent antibacterial properties, helped minimize contamination risks, thereby ensuring a clean and safe pharmaceutical production environment.

In addition, United Pharma’s HPL panels feature modular designs that shorten construction times by 84% compared to traditional methods. They eliminate the need for wet operations, thus reducing environmental pollution. Available in four surface types—glossy, textured, wood grain, and stone pattern—these panels offer more than 200 color options to meet clients' personalized needs.

Forging Ahead Amid Opportunities and Challenges

As globalization and the digital economy continue to develop, the cleanroom industry faces both unprecedented opportunities and intense competition, along with constantly evolving business environments at home and abroad. United Pharma keeps pace with technological trends, continuously improving product performance to provide customers with superior cleanroom solutions. Backed by a solid brand foundation, exceptional innovation capabilities, and a strong reputation among clients, United Pharma maintains a powerful presence in the cleanroom industry. Looking forward, the company will continue to invest in R&D, collaborate with research institutions, and explore new materials and technologies for cleanroom applications. By offering more comprehensive and high-quality solutions, United Pharma will continue to lead the development of the cleanroom industry.